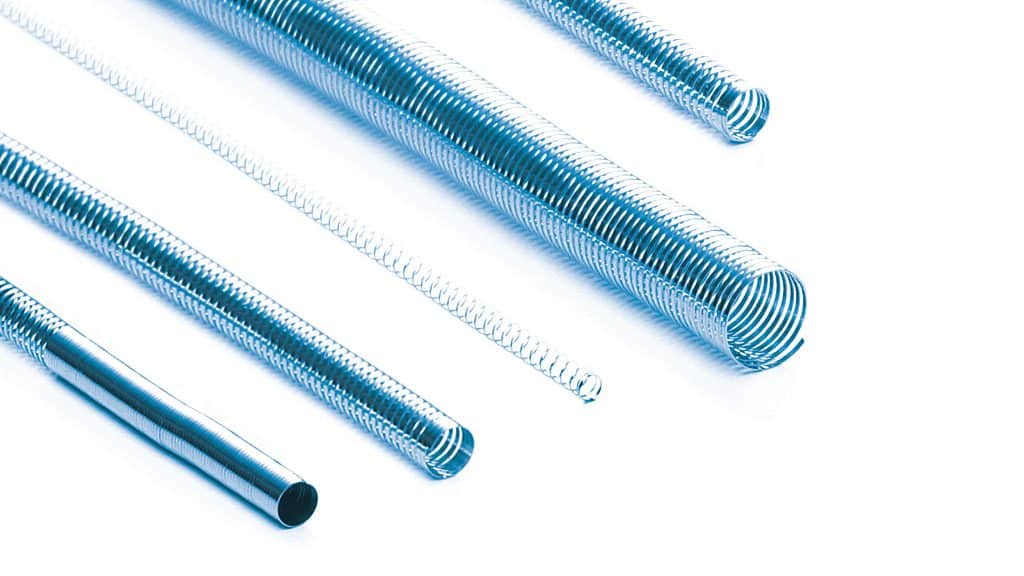

Increasing demand from top OEMs to diversify their product portfolios has required CWT to overcome manufacturing challenges associated with nickel titanium. Our engineering team’s ability to quickly produce samples and prototypes helps innovative startups fast track new product development.

Our long history with coiling stainless steel wire laid the foundation for our success with nitinol. To serve the ever changing needs of the industry, CWT has invested in dedicated equipment to its nitinol coil manufacturing line.

Nitinol Capabilities

Sizing and Specs

- Experience with all grades and finishes of Nickel Titanium

- Nitinol core wires with ground tapers and profiles

- Starting wire sizes as small as 0.005” OD up to 0.125” OD

- Nitinol coils made from round or flat wire

- Wire as small as 0.0008” in OD or thickness

- Computer-controlled parameters for pitch, length, and tension

- Custom-shaped Nitinol wireforms and assemblies

- Full machine shop for custom fixture manufacturing

- Nitinol k-wires and pins with threads and sharp tips

- Custom sized and shaped mandrels produced in-house

Custom Nitinol Coiling

CWT provides customized medical wire coiling solutions that meet or exceed design requirements needed by the top OEMs in the medical device industry.

Custom Nitinol K-Wires

With the ability to grind various geometries, our ability to manufacture orthopedic wires is unique. From K-wires (Kirschner wires), Steinmann pins, or fixation devices, CWT can help custom manufacture your medical component for you.

Nitinol Grinding

CWT offers medical grinding capabilities to manufacture guide wires, core wires, mandrels, hypotubes, K-Wires, orthopedic pins, needle prototypes, and components.

Nitinol Shape Setting

Nitinol can be shape set by placing an exact fixture and run through a time/temperature-controlled heat-set process with a quench to set the final shape.