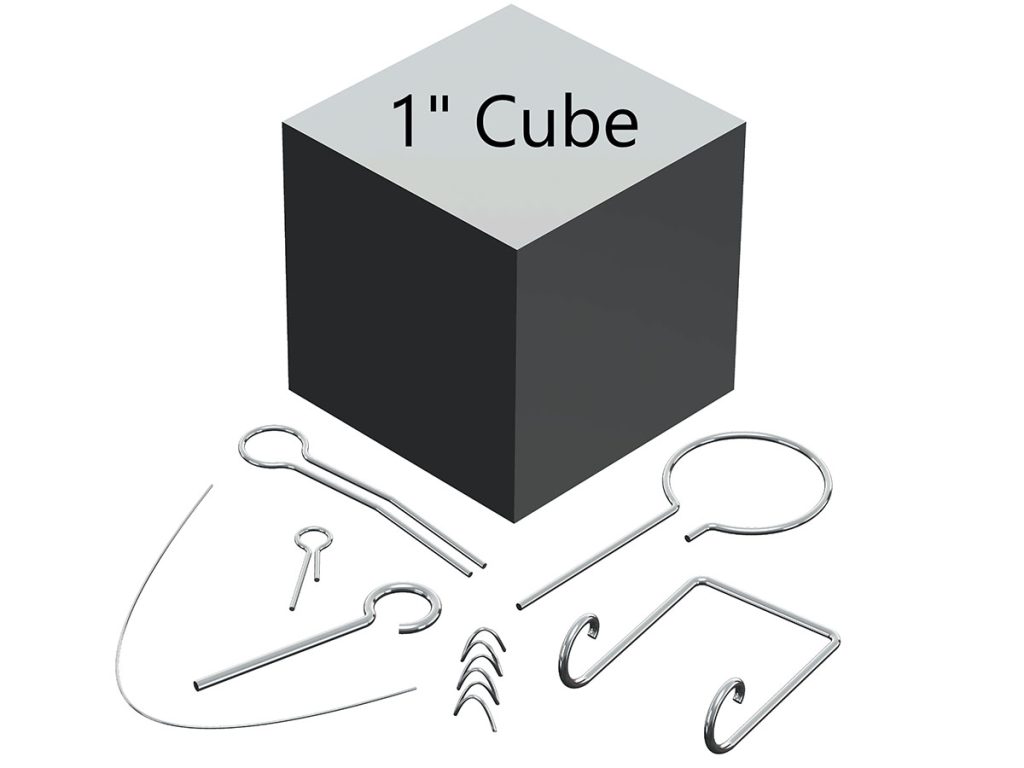

A variety of components can be manufactured using our custom medical wire forming process. These types of wire forms are used as stand-alone medical device components or as parts in larger assemblies. Clips, rings, links and other wire forming parts are combined with custom wire forming to produce the customer medical device requested.

Additionally, our custom wire forming can be done with an array of metals or alloys. In a custom wire forming process, our team can also make fine and microfine wires in various shapes such as round, flat, square or any custom designed shape.

Sizing and Specs

- Minimum wire size: 0.002” (0.05mm) OD

- Maximum wire size: 0.032” (0.80mm) OD

- 6-Axis capability for forming

- Bend radii at 1.5x wire OD

- Start from discrete lengths, spooled or coiled material

- Capable of bending hypotubes

- Tooling manufactured in-house

Custom Wire Forming

We use medical grade stainless steel and nitinol materials for forming products but we have used a variety of other materials in stock to create custom products. Our standard wire forming process works by feeding wire off a spool into a CNC wire forming machine with a cut-off. This enables us to provide competitive pricing and short lead times.

In addition to our high volume wire forming machinery, we are able to set up fixtures, hand jigs and presses to achieve a variety of complex shapes using secondary processes. We can manufacture small prototype orders for researchers up to large production orders for OEMs.

We have multiple processes set up to form wires. These processes can be as simple as manual jigs and fixtures or as complex as CNC wire forming machinery. No matter how we form your custom-designed wires, we have state of the art coordinate measuring systems to ensure that we adhere to your tolerance and specifications. Our highly trained operators treat each job with high-quality standards in mind.

Wire Forming Equipment

- CNC Wire Formers

- Coilers

- Four-slide, Multi-Slide

- Power Presses

- Custom Manual Jigs and Fixtures

The wire forming procedure is a combination of cutting, bending, drawing, straightening, flattening and stretching. Our machines operate within strict medical standards to ensure the wire forms adhere to all medical requirements. After the forming process, the finishing operation begins.

CNC Machinery

CWT is best suited to custom form wires with sizes in the .003″ to .032″ range based on our highly automated and high-precision CNC machinery. Our machinery can pull the wire off the spool, form it to your specification, cut off the component and start the next one. We have a large variety of stainless steel and nitinol wire sizes in stock for fast turnaround of your project.

Manual Fixtures

While not the most advanced technology, manual hand tools are still used often in manufacturing. For some custom wire forming projects, we will develop a fixture and manually form wires to specification. These manual fixtures can be used in our manufacturing process to precisely form your products. We have highly advanced vision systems and are able to achieve extremely tight tolerances while using manual wire forming tools.

From Lures to Medical Devices

Our typical customer is from the medical industry but we have formed wires for a wide variety of products including world-class bass lures, racking wires for retail, dental products, handles and a large variety of formed wire shapes. Every wire forming project receives the same amount of high-quality work and craftsmanship that customers have come to expect from us.

Custom Wire technologies is a custom wire form specialist. In addition to forming, we can do wire coiling, cutting, forming, heat treating, drilling, grinding, winding, welding, soldering, twisting, pressing and more! About the only thing that we can’t do is draw raw wire, we have a network of raw material manufacturers that we work with for raw wire.