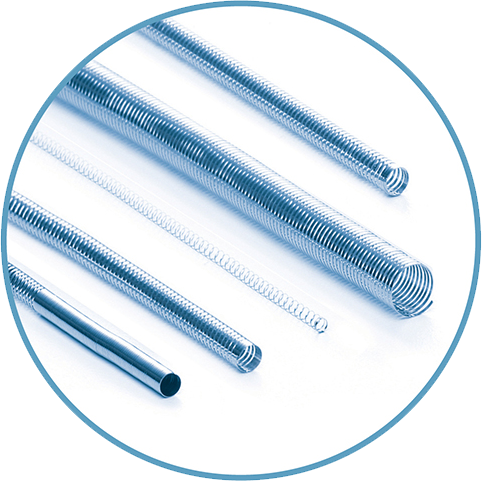

Nitinol coils offer unique properties which can be superior to stainless steel coils for certain use cases. It differs from stainless steel in several ways.

Nitinol is a metal alloy based on a roughly equal combination of Nickel and Titanium which gives it elastic shape memory properties such that it can be forced to return to its original shape when reacting to its external environment. Because of this super elasticity, nitinol coils can be more flexible than stainless steel, as well as kink resistant.

Designers are able to use the material’s super-elastic nature to their advantage just as they would with nitinol wire. Nitinol is an MRI (magnetic resonance imagining) compatible alloy.

Sizing and Specs

- Starting wire sizes from 0.005″ to 0.188″

- Typical wire sizes in stock from 0.001″ to 0.32″ diameter

- Minimum OD: 0.010”

- Maximum OD: 0.750″

Coil Options

We are a contract manufacturer of custom nitinol coils, meaning each product is made to order. Options include:

- Closed end

- Open end

- Variable pitch

- Variable diameter

- Step diameter

- Tapered diameter

- Dead coils

Coil Forming

Nitinol coils are typically formed by wrapping nitinol wire around a mandrel and then run through a time/temperature-controlled heat set process to “set the coil”. The mandrel OD will be the ID of the coil. This type of forming allows us to manufacture a variety of coil shapes and characteristics.

We have the capability to manufacture monofilar and multifilar nitinol coils using flat or circular nitinol wire, and then coil it around a mandrel to form the nitinol coils. The mandrel we use can have a variety of shapes (such as flat or tapered) to coil a custom profile.

Please contact us today for assistance with prepping your nitinol coil designs for manufacture.

For nitinol coil orders that require a fast turnaround, CWT stocks a wide array of nitinol wire sizes as part of our QwikCoil service.