With over 20 years of spring manufacturing experience, CWT manufactures custom compression springs to assist medical device OEMs, designers and researchers in a wide array of medical applications.

Compression Spring Options

As experts in compression springs, we are prepared to make recommendations for your custom compression spring to achieve the desired outcome for your medical device or standalone component, from wire sizes, spring materials, and other design or process engineering details.

The majority of our custom compression springs are used in medical applications. These types of applications include:

- Tube (catheters) reinforcement

- Guidewire springs

- Radiopaque marker springs

A compression spring is normally wound to a consistent diameter, however, we also manufacture:

- Multi-diameter springs

- Tapered compression springs

- Consistent pitch or variable pitch

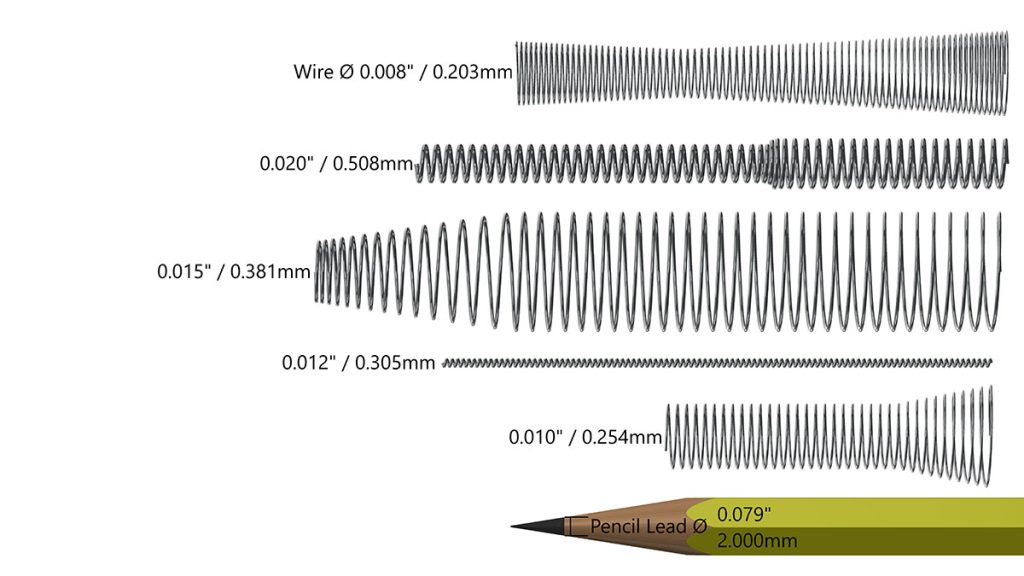

- Materials: choose from round wire or flat wire made out of stainless steel 304V or other spring tempered material

After we have manufactured your custom springs we also offer secondary processes such as electropolishing, spring assembly, spring setting and grinding, both in-house and with our trusted partners. We manufacture compression springs as stand-alone components or as part of larger assemblies.

Contract Custom Springs

CWT contract manufactures custom compression springs. We do not supply or stock standard compression springs for resale. We do however stock a wide variety of small diameter wire in stainless steel 304V, stainless steel 316LVM, and nitinol.

Due to our large stock of wire sizes, we have the ability to turnaround expedited and fast orders when needed. As a contract manufacturer, we build custom springs to customer design drawing specifications.

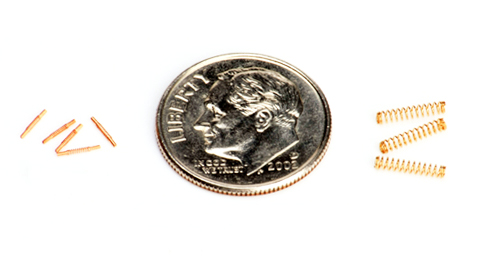

Micro Compression Springs

CWT is an expert in making small compression springs. There isn’t necessarily a Webster’s definition of micro-compression springs (or small compression springs or nano compression springs) but you can rest assured that we can make high-quality small springs for your next application. We have built micro-compression springs for small guidewires, syringes and a variety of other spring applications.

Typically micro-compression springs are used in some type of assembly. Secondary manufacturing processes are also available for the assembly and finishing of springs, including cleanroom assembly, soldering, laser welding, end grinding, stamping, ultrasonic cleaning, and electropolishing.

At our core, we are spring engineers who enjoy new and challenging manufacturing projects. From prototype springs to large productions, don’t hesitate to contact us with your micro compression spring manufacturing project!