As an ISO-certified manufacturer for decades, Custom Wire Technologies has provided advanced, high-precision medical coils to OEMs in the medical device industry. As a world-class provider, we understand the needs of your medical supply chain and deliver exceptional quality and engineering experience that’s second to none.

Medical Coil Capabilities

Custom Wire technologies (CWT) provides customized medical wire coiling solutions that meet or exceed design requirements needed by the top OEMs in the medical device industry today. Our wide range of material offerings, technical expertise, and unique processes provide an ability to produce complex medical coils with tight-tolerances for the most challenging of design specifications to-date.

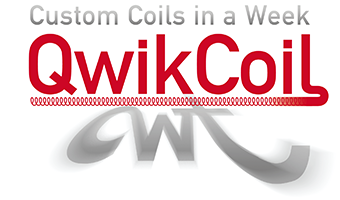

Sizing and Specs

- Wind wire and coil wire from 0.001″ to 0.032”

- Most common sizes: 0.008” to 0.032”

- ODs from 0.010” to 0.75″

- Maximum coil size: 0.25″

- Coil lengths up to 96” (dependent on application)

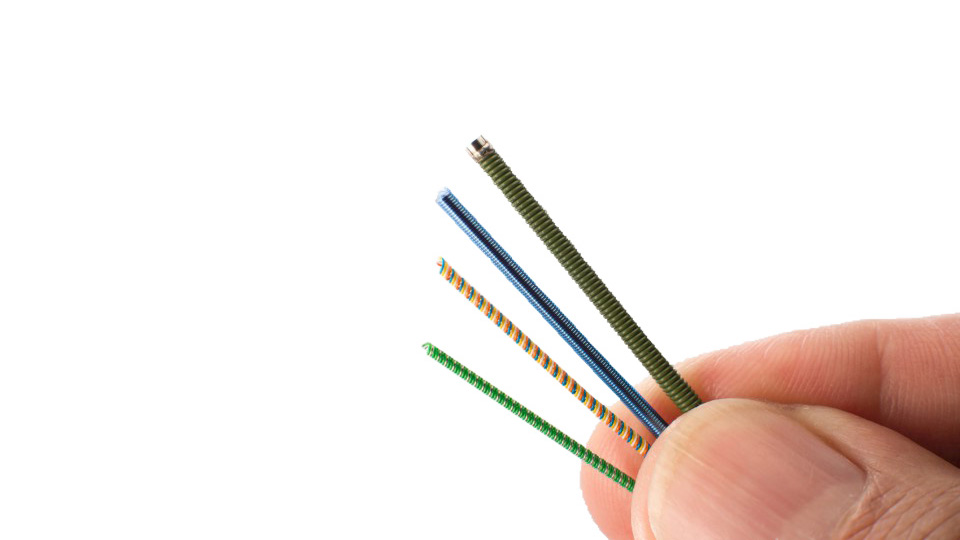

- Unifilar and multi-filar capability up to 6 filars

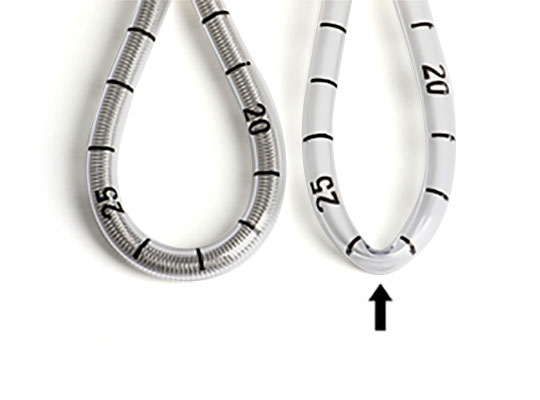

- Numerical machine controls to .0001 mm

- Tension and pitch controls with variation within single wound or coiled length

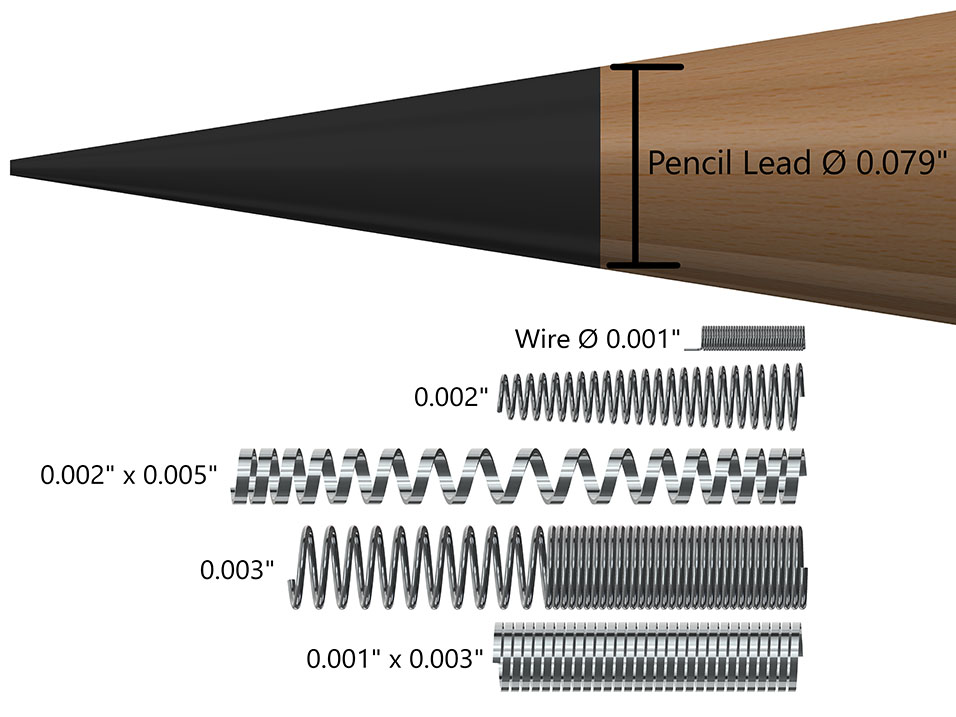

- Coil-reinforced tubing for catheters

Materials

Precious Metals

- Au (Gold)

- Pt (Platinum)

- Pt/W (Platinum-Tungsten)

- Pt/Ir (Platinum–Iridium)

- Ag (Silver)

Nitinol Coils

Nitinol-based coils are unique in several ways when compared to stainless steel variations. Nitinol’s shape memory characteristics allow for flexible, complex designs that react differently to environmental stress while maintaining the desired shape of your product design.

Reinforcement Wire Coils

Today’s medical tubing manufacturers demand high-performance products from their suppliers, and CWT delivers nothing less. Our fully-equipped laboratory enables our technicians to work efficiently with OEM’s through every step of the engineering process, ensuring a fully-functional, finished product for medical catheters & diagnostic devices.

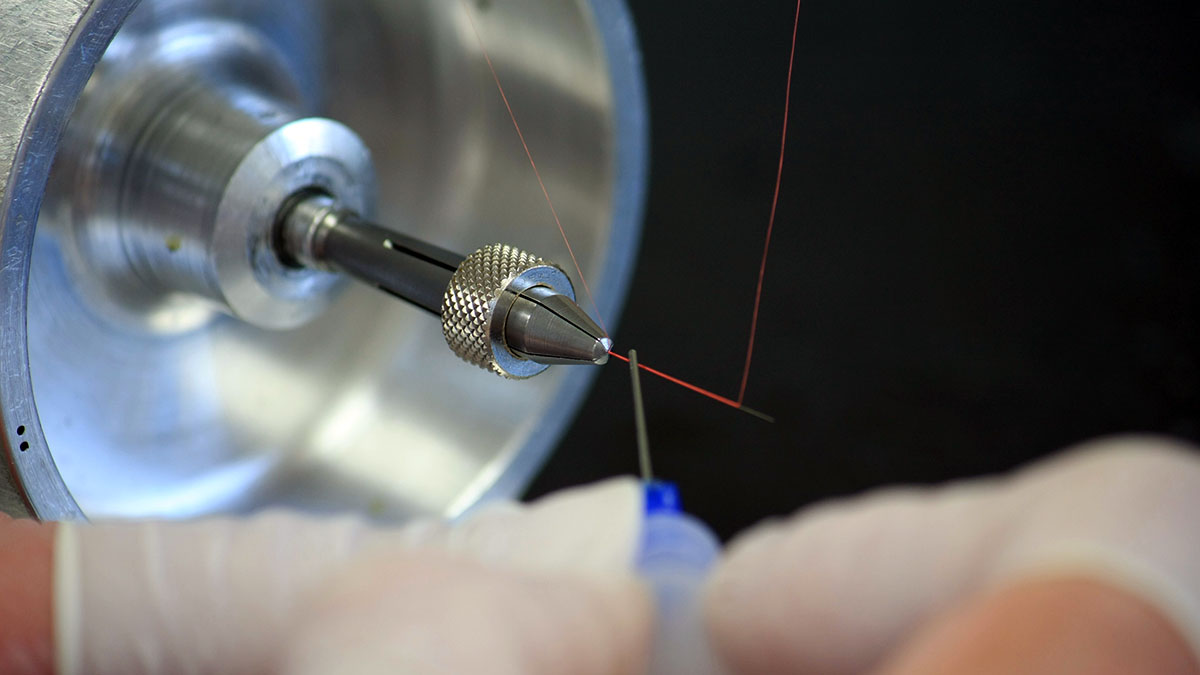

Fine & Micro-Fine Wire Medical Coiling

Custom Wire technologies (CWT) started with a single coiling machine and the idea that a company could be built out of adherence to high-quality standards and customer service. Our state-of-the-art production facility provides OEMs with customized solutions for minimally invasive medical coils from prototype applications through full, mass production orders.

Medical Coil Finishing

CWT provides value-added finishing services to OEMs that require specialized treatments and coatings for their fabricated products. Our wide range of serviceable materials, capabilities, and services are only matched by our superior customer support standards of excellence.

Unifilar Coils Only

- Coil ID from 0.006” and up

- Lengths up to 60”

- Closed wound or open pitched available

- Standard end cuts (axial)

Pricing

- 304V SS – $1,750 (20 coils)

- Nitinol #1 – $2,500 (20 coils)

Material must be in-stock to qualify.

Customer-supplied material is acceptable.

Certification included.

Stocked Materials

304V SS (spring temper) & Nitinol #1 (straight annealed)

| 304V SS & Nitinol Round Wire | 304V SS Flat Wire | Nitinol Flat Wire |

|---|---|---|

| .001” to .010”

Inquire about |

.001” x .005” .002” x .005” .002” x .008” .002” x .012” .003” x .009” .004” x .012” .006” x .015” |

.001” x .002” .001” x .003” .002” x .005” .002” x .008” .003” x .010” |

For all other orders please contact us for more information