Serving customers globally, we provide medical wire components for medical device manufacturers, instrumentation designers, dental surgical device suppliers, and medical & surgical device suppliers – both Class I and Class II.

Medical Wire Forming Capabilities

Wire Sizing and Specs

- Minimum wire size: 0.002” (0.05mm) OD

- Maximum wire size: 0.032” (0.80mm) OD

- 6-Axis capability for forming

- Bend radii at 1.5x wire OD

- Start from discrete lengths, spooled or coiled material

- Capable of bending hypotubes

- Tooling manufactured in-house

CWT specializes in custom wire forms made out of precision wires, fine wires, round wires and flat wires. Our highly automated CNC forming equipment is optimized for wire .032″ and smaller but don’t hesitate to contact us with larger diameter wire forming projects.

Medical Wire Materials

Stainless Steel

- 302

- 304, 304V, 304L

- 316, 316L, 316LVM

Inquire about others

Nickel Titanium (NiTi, Nitinol)

- Superelastic

- Shape memory

Titanium

- Pure commercial grades 1-4

- Ti-6Al-4V ELI

Other

- Aluminum

- Tool steels

Inquire about others

Nitinol Shape Setting

Nitinol offers unique properties which can be superior to stainless steel for certain use cases. Nitinol is a metal alloy based on a roughly equal combination of Nickel and Titanium which gives it elastic shape memory properties such that it can be forced to return to its original shape when reacting to its external environment.

Custom Medical Wire Fabrication

All CWT wire form fabrications are custom designed for Medical OEMs based on their desired specs.

Medical Device instruments are manufactured for various OEM suppliers and related medical device markets, including medical-surgical, dental surgical, and veterinarian surgical industries.

We also provide wire twisting for medical products. Our fine wire technicians can identify and accommodate your unique wire twisting requirements. We provide twisted medical wire components under these parameters: Base Wire Diameter, Twisted Wire Diameter, Overall Length of twisted wire, and Torque.

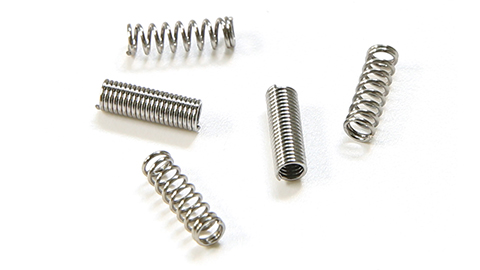

Medical Compression Springs

CWT fabricates custom medical compression springs to assist medical device OEMs, designers and researchers in a wide array of medical applications. Depending on your unique needs, we can assist with engineering, and recommend wire sizes, coiling materials and other design or process engineering details.