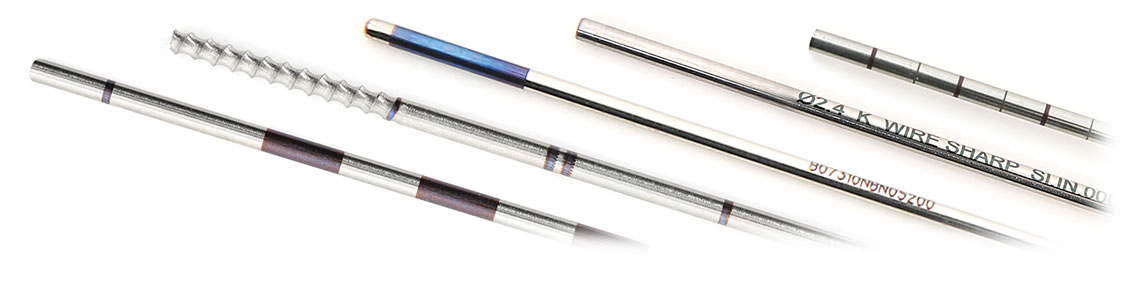

Our laser marking capabilities can add unique identifiers such as part numbers, lot numbers, descriptions, and company logos to a variety of parts. Additionally, we can add depth bands to guide wires, k-wires, and pins to present visual feedback to an end-user on how far a component may be inserted. We can also mark a variety of materials and sizes used within the medical industry. Contact us to learn more about how we can add laser markings to your product.

- Computer generated artwork, text, and shapes

- Linear or rotational marking capability

- 3-axis, 360° control of marking placement

- Marking capability on round or flat surfaces

- Marking tolerances to within ±0.001” (±0.025mm)

- Unlimited part length capability

- Unlimited number of marks or text per part

- Laser ablation of coatings for special applications

- Popular substrates include stainless steel and nitinol

Experience

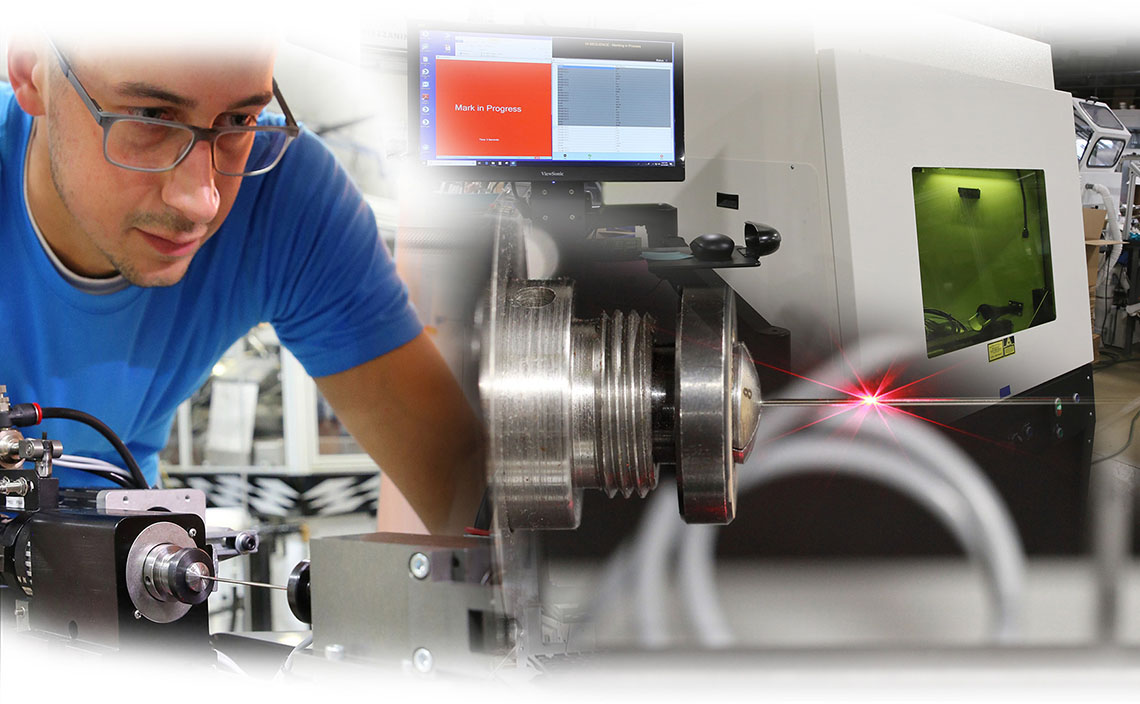

When Custom Wire technologies (CWT) began manufacturing products for the orthopedic industry in the late 2000s, we were quickly asked if we could add identifiers. These identifiers included lot numbers, batch numbers, or part numbers. We did not have the capability to support such requests in-house and as a result we looked to our suppliers. This process worked for the volume of parts CWT needed to produce, yet it added logistical issues, associated with lead times and shipments, however, it worked.

Jumping ahead to 2013, CWT added CNC grinding capability. As our ability to produce orthopedic wires improved, we saw an increase in demand and, subsequently, an increase in requests for markings. We continued to use our suppliers to provide this vital service. We eventually outgrew our suppliers’ capability to deliver a quality product in a timely manner. CWT made the decision to add marking equipment in 2018.

Designed around depth markings or identifying marks, this system would be the workhorse for all parts. Guidewires, k-wires, and pins can be marked to give end-users visual feedback or traceability. One unusual request into the removal of PTFE from a wire led to the discovery of coating ablation capability with our marking system. Another development activity led to the implementation of light-colored bands on nitinol with a dark oxide finish. With the demand for markings increasing, a second system capable of significantly faster cycle times was purchased in 2020.