Medical Wire Coiling

CWT coils stainless steel wire in microscopic cross-sections as required for catheter-related diagnostic devices. Depending on your specific medical wire coiling requirements and specifications, we use sophisticated, numerically controlled coiling equipment. Our coiling equipment is sensitized to provide complete process flexibility in controlling the characteristics and precision specifications required in your finished custom medical wire coils and coil components.

Custom Wire Capabilities

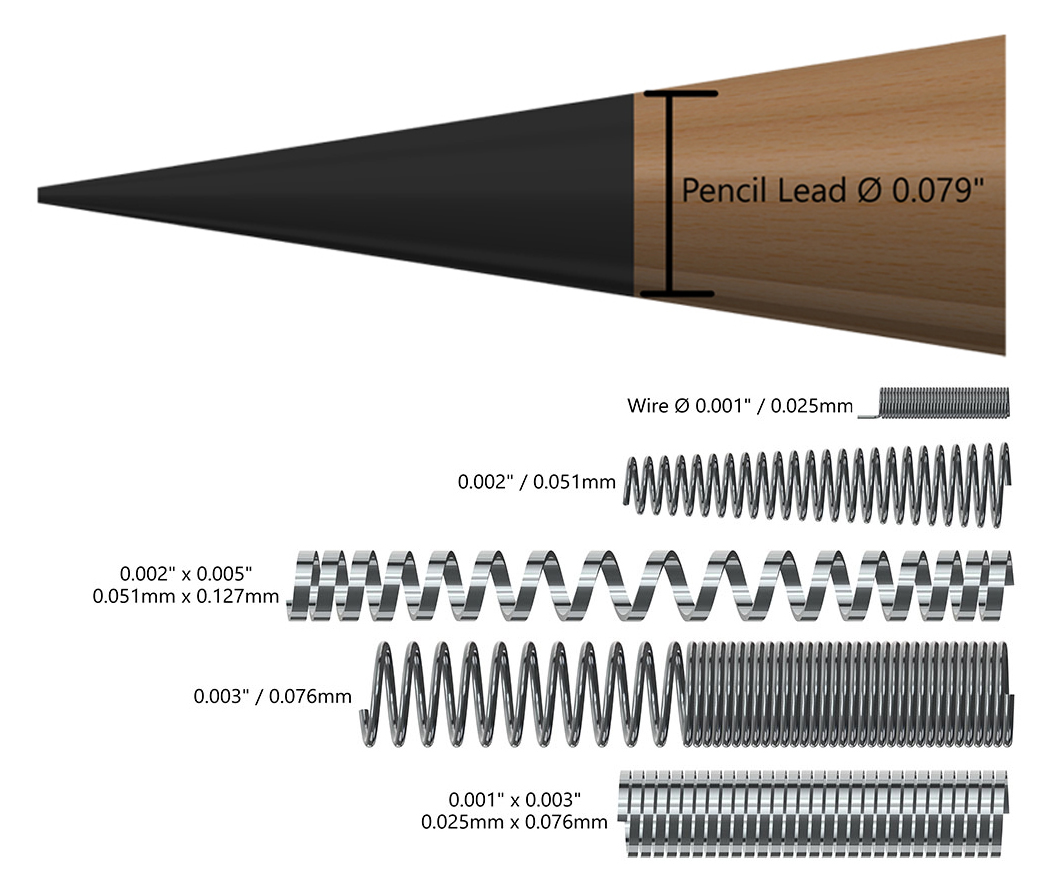

- Wind wire and coil wire as small as .001″

- Maximum coil size: 0.25″

- Numerical machine controls to .0001 mm

- Tension and pitch controls with variation within single wound or coiled length

- Catheter-reinforced coils of any length

Unifilar or Multifilar

Our CNC winding machinery has the ability to manufacture unifilar OR multi-filar windings – coiling up to 6 wires into a spring for complex medical devices.

Having multiple wires on a single spring enables engineers to achieve alternative coil properties, as well as the ability to wrap different types of material onto a single spring design for multi-sensor and multi-signal types of internal monitoring devices.

Competitive Lead Times

We understand the needs of a complex medical industry supply chain. Our customers around the world count on us to deliver the correct products, on time. With multiple high-precision CNC coiling machines, we are able to turn around orders fast and to your precise specifications. You may also take advantage of our special packaging so your coils are delivered tangle-free.

For your next medical wire coiling project, contact our custom wire specialists to learn how you can control your costs while achieving consistent finished parts within your required specs and prompt turnaround time.

Coil Specifications

CWT custom manufactures coils and springs with a variety of custom specs.

- Short-length and long-length coils up to 96” (dependent on application)

- Closed-end coils, ends ground flat, and open-end coils

- Custom dead coils

- Standard pitch and variable pitches

Stainless steel 304V spring temper material is typically used in round wire or flat form but a wide variety of materials including nitinol are available as options.

Custom Engineered

Customers come to us because they know we are experts in the field. Either send us a drawing or come to us with an idea for your coil, and we can help you through the process of engineering the perfect coil for your application.

CWT ONLY MANUFACTURES CUSTOM COILED COMPONENTS. You won’t find any standard or off-the-shelf wire coils, forms, or parts here. We specialize in unique, precision medical wire coiling, forming, and bending. Many of our custom medical coils or forms are often integrated with our cleanroom sub-assembly services.