Our specialty is in core wire centerless grinding. We are able to grind core wire lengths in excess of 10 feet with great precision. Our automation equipment is specialized to do both small and large core wire manufacturing runs. We work with customers at the cutting edge of medical device design including international OEMs and university researchers alike. We can help turn an idea into reality or we can be your source for a high-volume manufacturing partner.

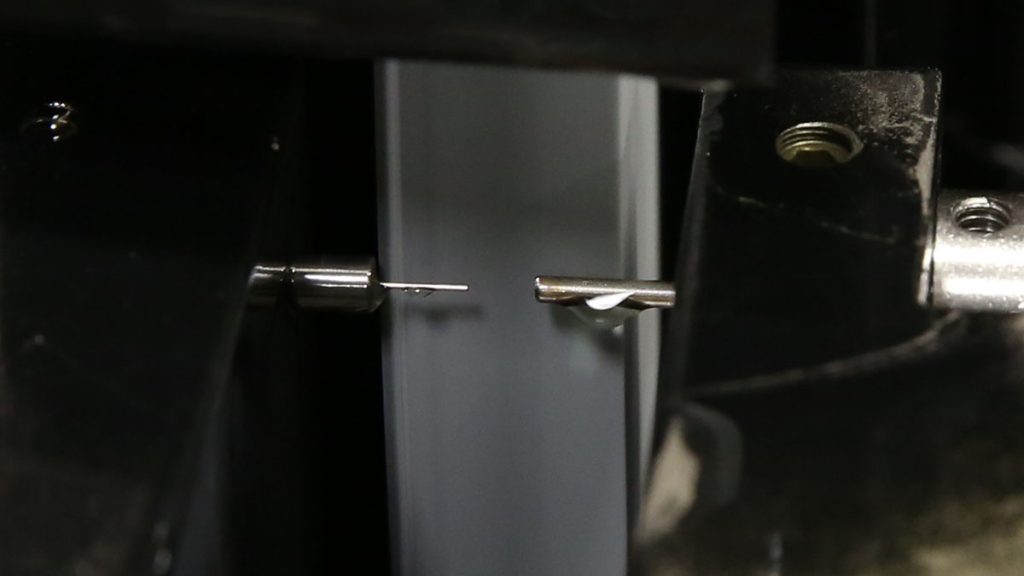

Many of our projects utilize stainless steel 304 and nitinol wire to produce cores wires. We can use PTFE-coated wire and grind the coating away or we can grind the wire first and then apply coatings. We can grind in excess of 10-foot lengths of wire with diameters between .006″ and .035″ in size.

We can change the flexibility characteristics of a core wire based on a tapered profile. We can increase or decrease the diameter in area to give it more flexibility. Larger diameter equals more stiffness. The same principal is true for length, we can induce more flex in a longer grind profile than one that is shorter.