Custom Wire Technologies is a contract manufacturer serving OEMs and researchers in the medical device industry and has more than 20 years of experience in wire forming concepts. Using medical grade stainless steel and nitinol materials, CWT’s standard wire forming process works by feeding wire off a spool into a CNC wire forming machine with a cut-off, enabling competitive pricing and short lead times.

Custom Wire Technologies is a contract manufacturer serving OEMs and researchers in the medical device industry and has more than 20 years of experience in wire forming concepts. Using medical grade stainless steel and nitinol materials, CWT’s standard wire forming process works by feeding wire off a spool into a CNC wire forming machine with a cut-off, enabling competitive pricing and short lead times.

Although CWT does not stock off-the-shelf wire forms or wire products, it does stock a large amount of raw wire to offer quick turnaround for customer projects. Jim Boldig, director of sales and engineering at CWT, explains in more detail how custom forming from wire spools equates to shorter lead times, saving its customers time and money.

“This is related to machine setup and efficiency,” says Boldig. “When setting up a machine to run from a spool, we can put a large quantity (20-30 lbs) of raw material onto the payoff (the piece of equipment to hold and help feed material into the machine). The large quantity allows us to keep running with less operator interaction. Less operator interaction and setup are cost-savings for our customers.” Automation is key, says Boldig. “Our forming equipment is capable of running unattended,” he explains. “With the right geometry, the machines can run over one or two hundred pieces per hour.”

Wire Forming Overview

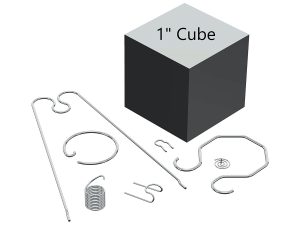

Custom wire forming can be done with an array of metals or alloys, in fine or microfine wires, and in various shapes. These wires can be used both as stand-alone medical device components and as parts in larger assemblies, where clips, rings, or links are combined with the wires to produce the medical device required. In addition to its high volume wire forming machinery, CWT is also able to set up fixtures, hand jigs and presses to achieve a variety of complex shapes using secondary processes. Skilled operators treat each job with high-quality standards in mind and can manufacture small prototype orders for researchers up to large production orders for OEMs.

Custom wire forming can be done with an array of metals or alloys, in fine or microfine wires, and in various shapes. These wires can be used both as stand-alone medical device components and as parts in larger assemblies, where clips, rings, or links are combined with the wires to produce the medical device required. In addition to its high volume wire forming machinery, CWT is also able to set up fixtures, hand jigs and presses to achieve a variety of complex shapes using secondary processes. Skilled operators treat each job with high-quality standards in mind and can manufacture small prototype orders for researchers up to large production orders for OEMs.

CNC wire forming machines are usually focused on fine wires, points out Boldig. “Our current capability with automation is as small as 0.05mm. This size is generally restricted to specific applications like radiopaque marker coils. However, when stepping up in size, like 0.4mm OD for example, we can get extremely competitive with a variety of forming geometries. Our equipment can run up to 0.8mm OD with stock tooling. We have created custom tooling to allow larger sizes like 1.6mm OD. If the customer believes the opportunity is worth the upfront resources, CWT will invest to make it a reality.”

Design Flexibility

Flexibility is particularly important for CWT’s customers, notes Boldig. “This ability increases our portfolio of capabilities all under the same roof. We often find ourselves performing manual operations to satisfy our customer’s requirements. Occasionally, we are using a piece of equipment to perform one step and then a separate manual operation to finish it. The specifics are in the details of the parts. Some details require an operator to see what is happening and assess the quality. We will use our engineering resources to solve a problem. If it cannot be run on a machine that does not mean it cannot be made.”

Being responsive and flexible allows CWT to serve customers globally, providing wire components for medical device manufacturers, instrumentation designers, dental surgical device suppliers, and medical & surgical device suppliers – both Class I and Class II. In addition to forming, CWT can perform wire coiling, cutting, forming, heat treating, drilling, grinding, winding, welding, soldering, twisting, pressing and more. About the only thing it doesn’t do in-house is draw raw wire, for which it relies on a strategic network of raw material manufacturers.

Stainless Steel vs Nitinol

“Shape setting nitinol has allowed more diverse offerings of products to the industry,” says Boldig of the nickel and titanium alloy which has ‘shape memory’ properties and can change shape depending on temperature. “Customers develop parallel paths between stainless steel and nitinol to determine which will be the best for their application. Testing them together helps identify a front runner at a quicker pace.

“From a forming capability, stainless steel is usually the more economical alternative due to its ability to be formed at the machine level, as nitinol requires fixtures and heat treatment, which relates to higher part costs,” explains Boldig.

“Each material has their advantages and disadvantages, and the customer will ultimately determine what is best for their project,” Boldig concludes. “We work with our customers to produce processes that work. The end goal is to find efficient and economical solutions.”

Read Also: Building a Strong Medical Wire Supply Chain

LET’S CONNECT!

To learn more about how Custom Wire technologies can serve you and your business, be sure to reach out! We look forward to hearing from you and learning how we can be of service