How Nitinol Has Innovated Medical Devices

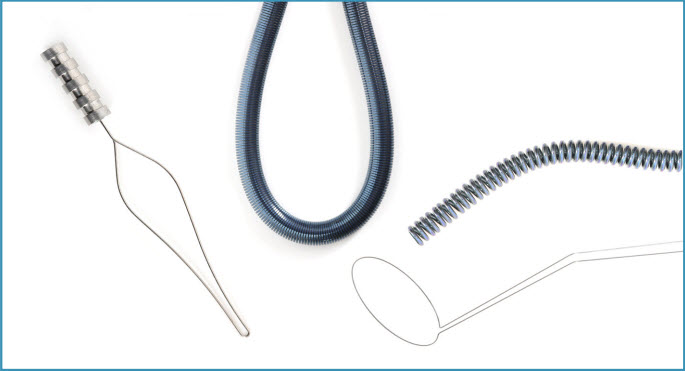

Imagine a guidewire application, which deals with a tortuous path within the body. Nitinol’s ability to take that strain, while avoiding kinks and not deforming, has obvious performance benefits. It ensures the proper placement and passage of the device being inserted. Nitinol’s unique superelastic properties and biocompatibility have made it an essential material for the medical device manufacturing industry, used in guidewires, core wires, orthopedic wires, and a variety of other specialty devices. During orthopedic surgeries, doctors can bend the material in ways that will not impact the wire’s performance when compared to other alloys like stainless steel, which doesn’t have anywhere near the flexibility or strain-resistance of nitinol.

Imagine a guidewire application, which deals with a tortuous path within the body. Nitinol’s ability to take that strain, while avoiding kinks and not deforming, has obvious performance benefits. It ensures the proper placement and passage of the device being inserted. Nitinol’s unique superelastic properties and biocompatibility have made it an essential material for the medical device manufacturing industry, used in guidewires, core wires, orthopedic wires, and a variety of other specialty devices. During orthopedic surgeries, doctors can bend the material in ways that will not impact the wire’s performance when compared to other alloys like stainless steel, which doesn’t have anywhere near the flexibility or strain-resistance of nitinol.

Nitinol (sometimes shortened to NiTi) was developed in the mid-1960s by composing an alloy using roughly 55.8% nickel and 44.3% titanium. According to John Corsten of Custom Wire Technologies, “Nitinol can take up to 8% strain without plastic deformation. In comparison, if you imagine a stainless steel wire, it can only take about 0.5% strain–beyond that, it will stay bent.”

Perhaps the biggest advantage of using nitinol as opposed to stainless steel is the biocompatibility. Stainless steel can only be used temporarily, and for specific procedures in the human body. Nitinol, on the other hand, can be used in the body for long periods of time and will not cause an adverse reaction, such as blood clotting, for the patient. Nitinol is the ideal material for the medical and dental fields for this reason.

Shape Setting Properties

The other unique property of nitinol is its ability to ‘remember’ the shape it was set in with a change in temperature. “Each given grade of nitinol has a transformation temperature above which the alloy is in an ordered cubic structure known as austenite,” explains Corsten. “When you go below that transformation temperature, the alloy changes to a monoclinic crystal phase called martensite.”

Transformation temperatures for superelastic grades of nitinol are between -20°C and 22°C. This has a huge potential for medical devices. When delivering a stent, for example, the shape will collapse under the transformation temperature, making it easier to insert into a catheter for delivery. Once inside the body, the natural body temperature means it will go right back to whatever shape it was set in.

CWT Expertise with Nitinol

Over the years, the CWT team has built up a vast amount of expertise when it comes to shape setting and grinding nitinol. The latter can be particularly challenging due to the material’s abrasive nature and increased flexibility. The company possesses a variety of customized tools to address concerns, all manufactured in-house.

CWT has been working with nitinol for more than a decade, right from the beginning of the material’s boom in the medical device industry. “In 2010, we had a customer request a nitinol suture threader,” explains Corsten. “The threader device required the use of nitinol so it could return to the original shape after passing through the small hole in the instrument. This allowed personnel to easily load the suture through the device.”

“It all just grew from there! In the past five years, it’s really gained traction to where we’re processing a tremendous amount of nitinol on a daily basis. I don’t think it will ever take over stainless steel, but I see the demand increasing and I see innovative devices being developed centered around nitinol.”

Supply Chain Stability

Custom Wire Technologies has a longstanding relationship with one of the premier suppliers of nitinol in the world, putting it in a unique position to offer the latest cutting-edge advancements to customers while supporting both small start-ups and larger OEMs with the manufacture of their innovative medical devices. Building strong relationships is paramount to delivering orders on time and is the foundation of being a trusted OEM provider.

Let’s Connect!

To learn more about how nitinol or Custom Wire Technologies can serve you and your business, be sure to reach out! We look forward to hearing from you and learning how we can be of service.

To find out more about nitinol and why it might be the perfect material for your next design,

download the whitepaper below.